The Ultimate Backyard Storage Solution: Constructing a Durable and Aesthetically Pleasing Wood Pallet Shed

The desire for efficient and attractive backyard storage is a common aspiration among homeowners. While pre-fabricated sheds offer convenience, constructing a shed from reclaimed wood pallets provides a unique opportunity to create a customized, cost-effective, and environmentally conscious storage solution. This comprehensive guide will detail the process of building an ultimate backyard storage shed utilizing repurposed wood pallets, emphasizing durability, aesthetics, and functionality.

I. Planning and Preparation: Laying the Foundation for Success

Before embarking on the construction process, meticulous planning and preparation are crucial for a successful outcome. This phase involves several key steps that will significantly impact the project's overall quality and longevity.

A. Site Selection and Assessment

Choosing the ideal location for your pallet shed is paramount. Consider factors such as:

- Accessibility: Ensure easy access for loading and unloading items.

- Sunlight and Shade: Balance sun exposure for natural light with sufficient shade to prevent excessive heat buildup.

- Drainage: Select a site with good drainage to prevent water accumulation and potential rot.

- Ground Conditions: Assess the ground's stability and consider the need for leveling or foundation preparation.

- Local Regulations: Check with local authorities regarding building permits and zoning regulations.

B. Pallet Sourcing and Inspection

The quality of the pallets will directly impact the shed's structural integrity. Prioritize pallets that are:

- Heat-treated (HT): These are safer and less likely to harbor pests.

- Structurally Sound: Inspect for rot, damage, or loose nails.

- Consistent Size and Type: Opt for pallets of similar dimensions for easier construction.

- Clean and Free of Debris: Thoroughly clean the pallets before use.

Consider sourcing pallets from local businesses or recycling centers, ensuring ethical and environmentally responsible procurement.

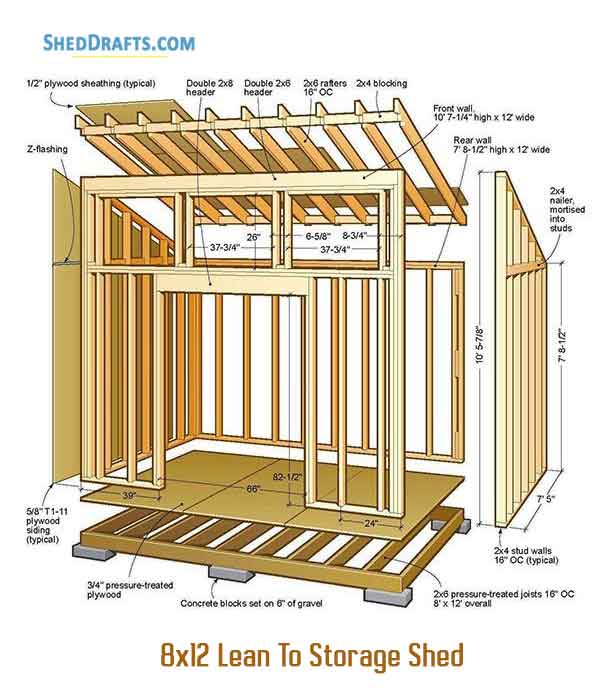

C. Design and Dimensions

Develop a detailed design plan, including the shed's overall dimensions, door placement, window placement (if desired), and roof style. Consider the amount of storage space needed and the size of the items to be stored. Sketching a design and creating a scaled drawing will greatly aid in the construction process. Factor in the dimensions of the pallets you've sourced to optimize material usage and minimize waste.

II. Construction: Building the Pallet Shed Frame

With the planning complete, the construction phase begins, focusing on building a robust and stable frame.

A. Foundation Preparation

Prepare a level foundation, whether it's a concrete slab, compacted gravel base, or a simple wooden platform. The chosen foundation must be capable of supporting the weight of the completed shed and its contents. Ensure the foundation is appropriately sized to accommodate the shed's dimensions.

B. Frame Assembly

Construct the frame using sturdy pallets, potentially reinforcing them with additional lumber for increased strength. Use galvanized screws or strong nails for fastening. The frame should be square and plumb, ensuring a stable structure. Pay attention to details such as corner bracing and appropriate spacing for walls and roof supports.

C. Wall Construction

Attach the pallets to the frame to create the walls. Ensure proper alignment and secure fastening. You may need to cut or adjust some pallets to fit perfectly. Consider adding extra bracing to strengthen the walls, particularly in areas subjected to high winds or stress.

D. Roof Construction

Construct the roof frame using additional lumber, ensuring it is appropriately sized and angled for adequate water runoff. The roof can be constructed using more pallets, providing a rustic aesthetic. Alternatively, consider using plywood or other roofing materials for a more weatherproof finish. Proper waterproofing is crucial to protect the shed's contents from the elements.

III. Finishing Touches: Enhancing Functionality and Aesthetics

Once the basic structure is complete, attention should turn to enhancing the shed's functionality and aesthetics.

A. Door and Window Installation

Install a sturdy door, ensuring a secure closure. Consider adding a lock for increased security. If windows are included in the design, install them carefully, ensuring weatherproofing to prevent drafts and water ingress. Choose appropriately sized and durable materials for both the doors and windows.

B. Exterior Finishing

Apply a weather-resistant sealant or stain to protect the wood from the elements. This will significantly prolong the shed's lifespan and enhance its aesthetic appeal. Choosing a color that complements the surrounding landscape will further improve the overall look.

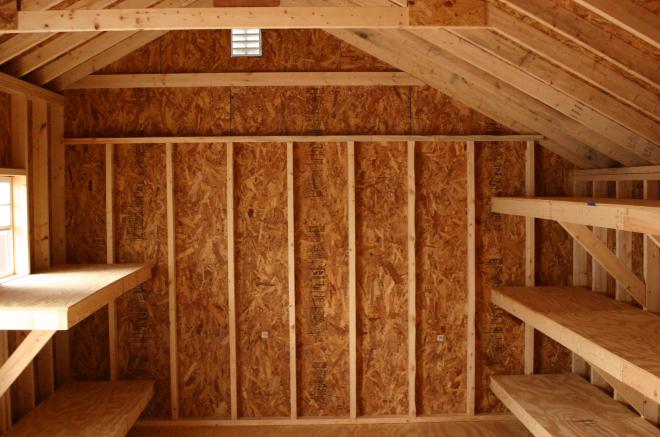

C. Interior Finishing

Consider adding shelves or other internal storage solutions to maximize the shed's usable space. Painting the interior walls can enhance the aesthetic appeal and provide a more welcoming storage space. Remember to use paints appropriate for wooden surfaces.

IV. Maintenance and Longevity: Preserving Your Investment

Proper maintenance is essential for ensuring the longevity of your pallet shed. Regular inspections, timely repairs, and proactive measures will significantly extend its useful life.

Regularly inspect the shed for any signs of damage, such as rotting wood, loose nails, or pest infestations. Address these issues promptly to prevent further deterioration. Periodically reapply a weather-resistant sealant or stain to protect the wood from the elements. Keep the shed clean and dry to prevent mold and mildew growth. By following these guidelines, your pallet shed will provide years of reliable and attractive storage.

Constructing a backyard shed from reclaimed wood pallets offers a unique blend of cost-effectiveness, environmental responsibility, and aesthetic appeal. By carefully following the planning, construction, and maintenance guidelines outlined in this comprehensive guide, you can create an ultimate backyard storage solution that meets your specific needs and enhances the overall beauty of your outdoor space. Remember, attention to detail throughout the process is crucial for achieving a durable and aesthetically pleasing result.